Xa kuthelekiswa nentsimbi, iifiber zeglasi eziqinisiweyo zinezinto ezikhaphukhaphu kunye nobuninzi obungaphantsi kwesinye kwisithathu sentsimbi.Nangona kunjalo, ngokwamandla, xa uxinzelelo lufikelela kwi-400MPa, imivalo yensimbi iya kuba noxinzelelo lwesivuno, ngelixa amandla okuqina ezinto ezidibeneyo zeglasi anokufikelela kwi-1000-2500MPa.Xa kuthelekiswa nezixhobo zentsimbi zemveli, izinto ezidityanisiweyo zefiber zeglasi zinesakhiwo esingafaniyo kunye ne-anisotropy ecacileyo, eneendlela zokungaphumeleli ezintsonkothileyo.Uphando lovavanyo kunye nethiyori phantsi kweentlobo ezahlukeneyo zemithwalo inokubonelela ngengqiqo ebanzi yeepropathi zabo zomatshini, ngakumbi xa zisetyenziswa kwiinkalo ezifana nezixhobo zokukhusela zelizwe kunye ne-aerospace, efuna uphando olunzulu kwiimpawu zabo kunye neempawu zoomatshini ukuhlangabezana neemfuno zabo kwi-aerospace. indawo yokusetyenziswa.

Oku kulandelayo kwazisa iimpawu zomatshini kunye nohlalutyo lomonakalo emva kwe-glass fiber composite materials, ukunika isikhokelo sokusetyenziswa kwesi sixhobo.

(1) Iimpawu zokuqina kunye nohlalutyo:

Uphando lubonise ukuba iipropathi zomatshini zefiber yeglasi eyomeleziweyo ye-epoxy resin composite imathiriyeli ibonisa ukuba amandla okuqina kwicala elinxuseneyo lemathiriyeli makhulu kakhulu kunalawo akwicala elithe nkqo lefiber.Ke ngoko, ekusetyenzisweni okusebenzayo, isalathiso sefiber yeglasi kufuneka sigcinwe sihambelana ngokusemandleni kunye nesikhokelo sokuqina, sisebenzisa ngokupheleleyo iipropathi zayo ezibalaseleyo.Xa kuthelekiswa nentsimbi, amandla okuqina aphezulu kakhulu, kodwa ukuxinana kusezantsi kakhulu kunoko kwentsimbi.Kuyabonakala ukuba, Iipropathi ezibanzi zoomatshini bezinto ezihlanganisiweyo zeglasi ziphezulu kakhulu.

Uphando lubonise ukuba ukonyusa isixa sefayibha yeglasi eyongezwe kwizinto ezidityanisiweyo ze-thermoplastic ngokuthe ngcembe kwandisa amandla obunzima bezinto ezidibeneyo.Isizathu esona sizathu kukuba njengoko umxholo wefiber yeglasi ukhula, iifiber ezininzi zeglasi kwizinto ezidibeneyo zixhomekeke kumandla angaphandle.Kwangaxeshanye, ngenxa yokunyuka kwenani leentsinga zeglasi, i-resin matrix phakathi kwefiber yeglasi iba bhityile, nto leyo enceda ngakumbi ekwakhiweni kweefreyimu eziqinisiweyo zeglasi.Ke ngoko, ukonyuka komxholo wefiber yeglasi kubangela uxinzelelo ngakumbi ukuba ludluliselwe kwi-resin ukuya kwifiber yeglasi kwizinto ezihlanganisiweyo phantsi kwemithwalo yangaphandle, ngokufanelekileyo ukuphucula iimpawu zabo zokuqina.

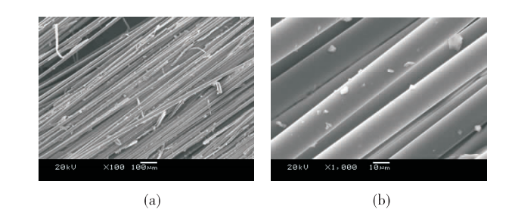

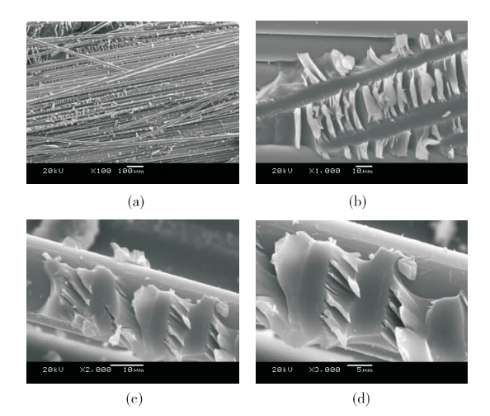

Uphando malunga novavanyo lokuqina lwegilasi yefiber engaxutywanga nepolyester yemathiriyeli edityanisiweyo ibonise ukuba indlela yokusilela kwefiber yeglasi eyomeleziweyo yemathiriyeli edityanisiweyo kukungaphumeleli kwendibaniselwano yeentsinga kunye ne-resin matrix ngokuskena i-electron microscopy yecandelo le-tensile.Umphezulu wokuqhekeka ubonisa ukuba inani elikhulu lemicu yeglasi itsalwa ngaphandle kwe-resin matrix kwicandelo lokuqina, kwaye umphezulu wemicu yeglasi ekhutshiweyo kwi-resin matrix igudileyo kwaye icocekile, inamaqhekeza eresin ambalwa kakhulu anamathela kumphezulu. yeentsinga zeglasi, ukusebenza kukuqhekeka okunqabileyo.Ngokuphucula unxibelelwano phakathi kweefiber zeglasi kunye ne-resin, amandla okufakela ezi zimbini aphuculwe.Kwicandelo le-tensile, uninzi lwamaqhekeza eresin ye-matrix kunye nokudityaniswa okungaphezulu kwemicu yeglasi kunokubonwa.Uqwalaselo lolwandiso olongezelelweyo lubonisa ukuba inani elikhulu lemibhobho yeresin ye-matrix kumphezulu wemicu yeglasi ekhutshiweyo kwaye ibonisa ikama njengelungiselelo.I-fracture surface ibonisa i-ductile fracture, enokufikelela kwiimpawu ezingcono zomatshini.

(2) Ukugoba ukusebenza kunye nohlalutyo:

Uvavanyo lokudinwa olunamanqaku amathathu luqhutywe kwiipleyiti ezingafaniyo kunye nemizimba yokulahla i-resin yefiber yeglasi eyomeleziweyo ye-epoxy resin composite materials.Iziphumo zabonisa ukuba ukugoba kokuqina kwezi zibini kuqhubekile nokuhla ngokunyuka kwamaxesha okudinwa.Nangona kunjalo, ukugoba kokuqina kwefayibha yeglasi eyomeleziweyo iipleyiti ezingafaniyo zaziphezulu kakhulu kunomzimba wokujula, kwaye inqanaba lokuhla lokugoba lalicotha.Bekukho amaxesha okudinwa ngakumbi okuqhekeka okuvela ekuhambeni kwexesha, nto leyo ebonisa ukuba ifayibha yeglasi inefuthe eliphuculweyo ekusebenzeni kokugoba kwematrix.

Ngokungeniswa kwemicu yeglasi kunye nokunyuka ngokuthe ngcembe kwiqhekeza levolumu, amandla okugoba ezinto ezidibeneyo nawo ayanda ngokufanelekileyo.Xa i-fiber volume fraction i-50%, amandla ayo okugoba ngawona aphezulu, angama-21.3% aphezulu kunamandla okuqala.Nangona kunjalo, xa i-fiber volume fraction i-80%, amandla okugoba ezinto ezidibeneyo abonisa ukwehla okukhulu, okungaphantsi kwamandla esampuli ngaphandle kwefayibha.Ngokuqhelekileyo kukholelwa ukuba, Amandla aphantsi ezinto eziphathekayo anokuba ngenxa ye-microcracks yangaphakathi kunye ne-voids evimbela ukuhanjiswa okusebenzayo komthwalo nge-matrix ukuya kwimicu, kwaye phantsi kwamandla angaphandle, i-microcracks yanda ngokukhawuleza ukwenza iimpazamo, ekugqibeleni ibangele umonakalo. Ukudityaniswa kokudityaniswa kolu lwazi lwegilasi oludityanisiweyo luxhomekeke ekuhambeni kwe-viscous yeglasi yefayibha matrix kumaqondo obushushu aphezulu ukusonga iintsinga, kwaye imicu yeglasi egqithisileyo ithintela kakhulu ukuhamba kwe-viscous ye-matrix, ibangela inqanaba elithile lomonakalo ekuqhubekeni phakathi. ujongano.

(3) Ukusebenza kokumelana nokungena:

Ukusetyenziswa kwefiber ephezulu yeglasi eyomeleziweyo yezixhobo ezihlanganisiweyo zobuso kunye nomva wesikrweqe sokusabela kunokumelana nokungena okungcono xa kuthelekiswa nentsimbi yealloyi yemveli.Xa kuthelekiswa nentsimbi yealloyi, imathiriyeli yeglasi yefibre yobuso kunye nomva wesikrweqe esiqhushumbayo esisabelayo inamaqhekeza amancinci ashiyekileyo emva kokuqhushumba, ngaphandle kwamandla okubulala, kwaye inokuphelisa ngokuyinxenye isiphumo sesibini sokubulala isikrweqe sokuqhushumba.

Ixesha lokuposa: Nov-07-2023